The Growth and Harvesting of Bamboo: A Sustainable Resource

Bamboo, known for its remarkable growth rate and versatility, is a sustainable resource that has gained popularity in recent years. In this section, we will explore the growth and harvesting process of bamboo, shedding light on its environmental benefits and importance as a raw material for various industries.

Bamboo is a type of grass that belongs to the family Poaceae. It is one of the fastest-growing plants on Earth, capable of reaching its mature height within three to five years. This rapid growth is due to its unique rhizome root system, which sprouts new shoots every year. Once established, the rhizomes expand horizontally, creating a dense network that promotes the efficient absorption of nutrients and allows the plant to spread.

Another significant aspect of bamboo's growth is its ability to thrive in diverse climates and environments. It can be found in tropical rainforests, as well as in temperate regions, making it a versatile plant that can adapt to various ecological conditions.

Harvesting and Regeneration

When it comes to harvesting bamboo, it's important to prioritize sustainable practices. Harvesting bamboo is typically done by cutting the mature culms, which are the woody stems of the plant. The timing of the harvest depends on the specific bamboo species, but it typically occurs when the culms reach their maximum strength and diameter.

To ensure the continued growth and regeneration of bamboo, proper harvesting techniques must be employed. When culms are cut, new shoots will sprout from the remaining rhizomes, replenishing the plant. It is crucial to avoid overharvesting, as this can negatively impact the bamboo population and its ability to regenerate.

Environmental Benefits

The growth and harvesting of bamboo offer numerous environmental benefits, making it an attractive sustainable resource. Firstly, bamboo absorbs large amounts of carbon dioxide (CO2) and releases oxygen into the atmosphere, aiding in the fight against climate change. As bamboo rapidly matures, it sequesters carbon at a much higher rate compared to other trees.

Additionally, bamboo plays a crucial role in soil conservation. The extensive root system of bamboo helps prevent soil erosion, stabilizes slopes, and protects against landslides. This is particularly valuable in regions prone to heavy rainfall or areas where deforestation has led to soil degradation.

Furthermore, bamboo plantations require minimal water, as they have natural resistance to pests and diseases. Unlike many traditional crops, bamboo does not require harmful pesticides and fertilizers. Its natural antimicrobial properties also contribute to its low maintenance needs.

Industrial Applications

Bamboo's sustainable qualities have made it a sought-after material for various industries, including construction, furniture production, and textile manufacturing. Its strength, durability, and flexibility make it an excellent choice for structural applications, such as flooring, beams, and scaffolding. Bamboo-based textiles, such as clothing and bedding, are prized for their softness, breathability, and moisture-wicking properties.

Additionally, bamboo is increasingly used in the production of sustainable packaging, paper, and even bioenergy. Its versatility and growing availability have allowed for innovative uses, replacing less sustainable alternatives and reducing the ecological footprint of various sectors.

The growth and harvesting of bamboo present a compelling case for its status as a sustainable resource. With its rapid growth, regenerative properties, environmental benefits, and wide range of applications, bamboo has become a key player in the shift towards more eco-friendly practices across numerous industries.

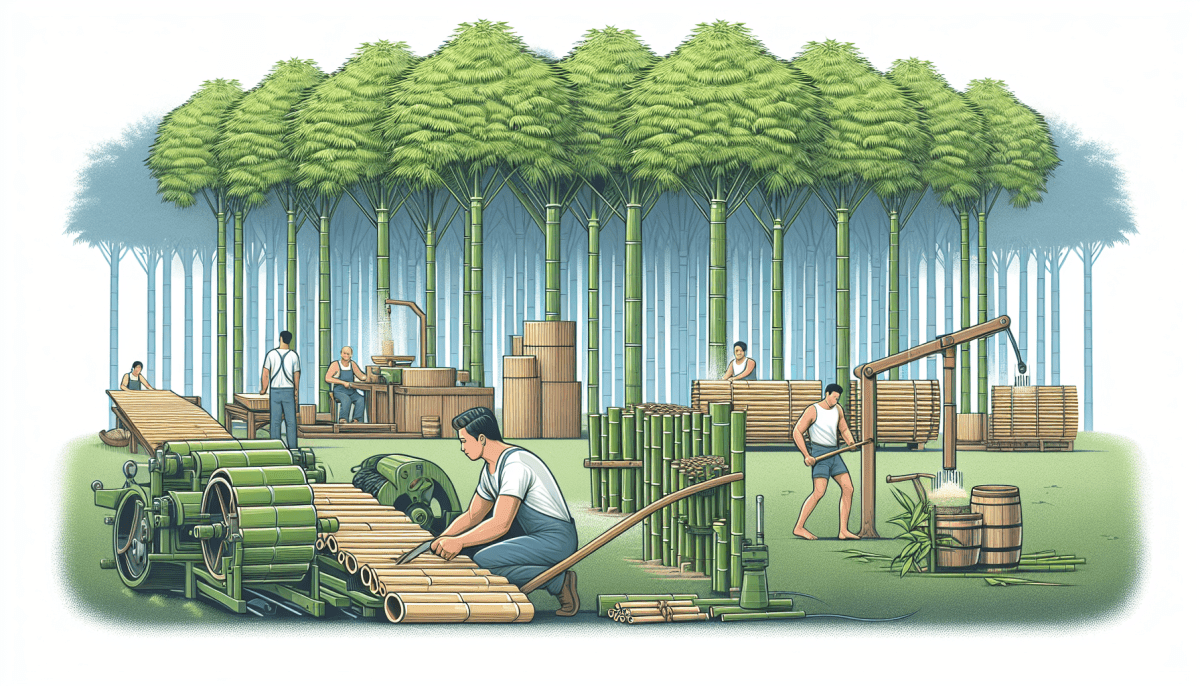

Bamboo Processing Techniques: From Raw Bamboo to Usable Material

Bamboo, a versatile and sustainable material, undergoes several processing techniques before it can be transformed into a usable product. Let's explore the steps involved in taking raw bamboo and converting it into a variety of bamboo products.

1. Harvesting and Selection

The first step in bamboo processing is the careful selection and harvesting of the raw bamboo. Harvesting is usually done when the bamboo reaches its peak maturity, which ensures optimal strength and durability. Selected bamboos are then cut using specialized tools, ensuring minimum damage to the remaining plant and the surrounding environment.

2. Cleaning and Treatment

Once the bamboo is harvested, it undergoes a thorough cleaning process to remove all impurities, such as dust, dirt, and outer skin. This cleaning ensures hygiene and prepares the bamboo for further treatment. Depending on the intended use and product requirements, treatment methods like boiling, steaming, or chemical treatment may be employed to enhance the bamboo's durability and make it resistant to pests, fungi, or mold.

3. Drying and Preservation

After treatment, bamboo needs to be dried to reduce its moisture content. Drying can be done naturally by allowing the bamboo to air-dry or through artificial processes like kiln drying. Proper drying ensures stability, prevents warping or cracking, and increases its lifespan. To preserve the bamboo and protect it from insects or decay, it may be treated with natural preservatives or coatings.

4. Sizing and Splitting

Once the bamboo is ready, it is then sized and split into usable sections according to the specific product requirements. Sizing may involve cutting the bamboo into different lengths, diameters, or thicknesses. Splitting refers to the process of carefully dividing the bamboo into strips or slats, which can be used for various applications like weaving, construction, or furniture making.

5. Treatment for Further Enhancement

Depending on the desired end product, additional treatments may be necessary. Techniques like bleaching, staining, or carbonizing can be employed to give bamboo a different color or enhance its appearance. These treatments not only add aesthetic value but can also make the bamboo more resistant to water, fire, or other specific environmental factors.

6. Joining and Finishing

Once the bamboo has been processed and treated, it can be shaped, joined, and finished according to the desired product. This may involve cutting, bending, and gluing bamboo pieces together to create intricate structures or designs. Finishing techniques like sanding, polishing, or applying varnish provide a smooth surface, further enhancing the product's appeal and durability.

Overall, bamboo processing techniques play a vital role in transforming raw bamboo into a wide range of useful and sustainable products. These techniques not only preserve the inherent strength and natural beauty of bamboo but also ensure the longevity and adaptability of the final products.

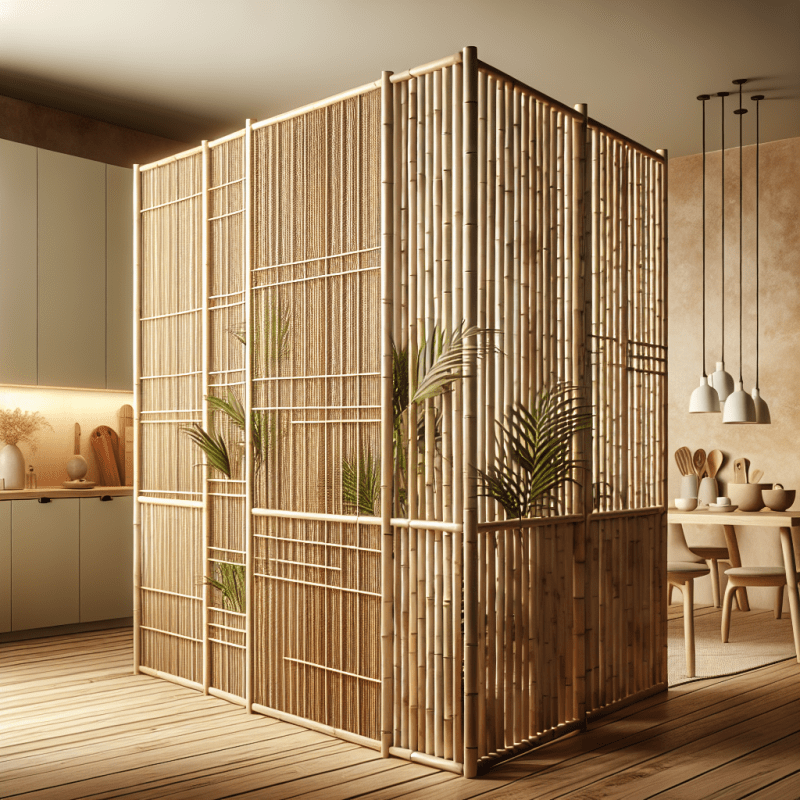

Manufacturing and Design Processes: Creating Versatile Bamboo Products

Bamboo products have gained immense popularity in recent years due to their sustainability, durability, and unique aesthetic appeal. However, the process of manufacturing these versatile products involves several intricate design and production techniques. Let's delve into the fascinating manufacturing and design processes that enable the creation of these remarkable bamboo products.

1. Sourcing and Selection of Bamboo

The entire manufacturing process begins with the careful selection of bamboo. Only mature bamboo stalks, typically aged five years or older, are suitable for high-quality products. The selection criteria include factors such as diameter, thickness, and overall quality of the bamboo stalks. Once selected, these stalks are cut down and transported to the manufacturing facilities.

2. Bamboo Treatment and Processing

Upon reaching the manufacturing facility, the bamboo stalks undergo meticulous treatment and processing. The treatment process involves removing the outer layer, nodes, and any possible insects or fungi present in the stalks. This ensures the cleanliness and longevity of the final product. The processed bamboo stalks are then cut into desired sizes and shapes using specialized tools and machinery.

3. Design and Craftsmanship

The design and craftsmanship play a crucial role in creating versatile bamboo products. Skilled artisans and designers work closely to transform the processed bamboo into functional and aesthetically pleasing items. Through intricate joinery techniques, bamboo can be fashioned into furniture, homeware, flooring, and even architectural elements. The designers carefully consider the natural patterns and unique characteristics of bamboo to create visually striking designs.

4. Drying and Finishing

After the initial crafting process, the bamboo products undergo a meticulous drying procedure. This removes any remaining moisture present in the bamboo, preventing warping or cracking. Various drying techniques, such as kiln drying or air drying, are employed depending on the specific product requirements. Once thoroughly dried, the products go through a finishing process where they are sanded, polished, and sometimes treated with natural oils or finishes for added protection and beauty.

5. Quality Control and Testing

To ensure the durability and quality of the final products, stringent quality control measures are implemented. Bamboo products go through rigorous testing, including load-bearing tests, impact resistance tests, and moisture resistance tests. Only the products that meet the highest standards and pass the quality checks are approved for distribution.

In conclusion, the manufacturing and design processes behind bamboo products encompass various stages, ranging from sourcing and processing of bamboo stalks to design and craftsmanship, and finally, to finishing and quality control. By adhering to sustainable practices and utilizing the natural versatility of bamboo, manufacturers are able to create an array of astonishing products that not only enhance our living spaces but also contribute towards a greener future.